Copyright © 2015 Powergrade Ltd. All rights reserved.

Jaguar Land Rover requested our help with a problem on their new F-

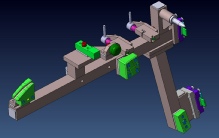

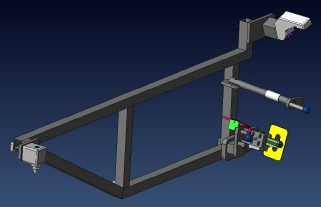

Our fixture design included many small assemblies working separately and in conjunction with other assemblies on the fixture i.e. fork assembly, fork locking assembly and telescopic pivoted rod assembly etc…

We analysed and carefully chose material for the fixture to reduce its weight without reducing its strength; we also considered the ergonomic factors to make it safe and easy for the assembly line personnel using it.

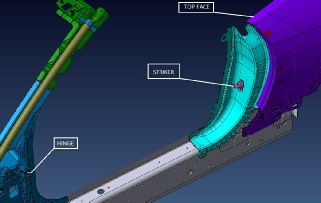

The door striker fixture swivels around hinge pin. When it swings towards a car’s body the magnetic fork holds and locates the striker in the proper position. The mylar at the top checks the position of striker at Z axis as it rests on top face of the body so there won’t be a gap between door and car body. The mylar at the bottom ensures the position of striker in Y axis making sure the striker sits in place and the door will engage with it, ensuring the door in the closed position is flush with the adjacent panels. A telescopic pivot locking rod will lock around the back side of door holding fixture firm and preventing it from swinging back. The car assembler will tighten the screws of striker at this point, disengage all clamps and will swing back the fixture.

We designed and manufactured this fixture in our well equipped facility with our dedicated team of designers, tool makers and other departments in our company.

Case Studies

F-Type Door Striker Fixture:

A form tool was cad designed and the parts were pressed, then hand trimmed and the edge was dutch-

The holes were drilled and the ancillary brackets were pop riveted into position.

The hole positions and the form was checked on our CMM machine and the parts were fitted to an engine for a final check.

We were approached by Caterpillar because the original drawings and tooling for this part had been lost. To add to the difficulties faced, the only sample part which could be provided was a well worn specimen from a used vehicle. They challenged us to reverse engineer the heat shield from just this poor sample :

We digitally scanned the heat shield and a single skin iges cad model was created from the scan. A Powergrade CAD engineer then turned the single skin into a double skin component by offsetting the skin by the material thickness.

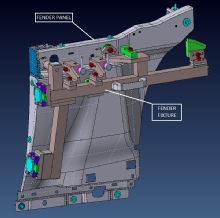

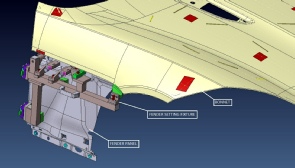

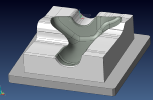

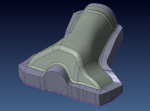

This fixture is designed to assemble the fender panels on Jaguar Land Rover cars. It comprises of location pins, mylars, location strips and spring loaded holding clamps.

The fender panel is clamped to the fixture using location pins and held firmly by spring loaded clamps. This fixture and panel is then placed onto the body. Mylars on the fixture coordinate with the edges of bonnet to give the exact location and orientation of the panel. Panels can be screwed down to the car body and by releasing the spring clamps the fixture can be easily removed.

The main frame of the fixture and mountings are manufactured from specific aluminium alloys. The mountings are then coated with our own in-

We take pride in having introduced this technique to Jaguar Land Rover. We always endeavour to utilize new techniques over conventional ones to deliver the best satisfaction to our customers.